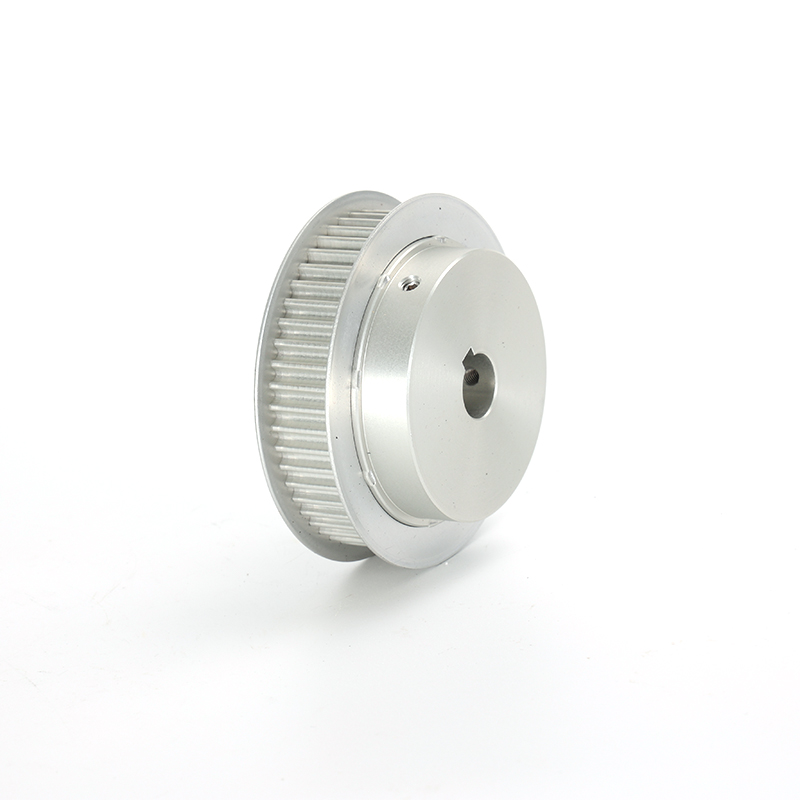

Synchronized pulley is an important part of the transmission system, and its material selection has an important impact on transmission performance and durability. Different materials have different characteristics and performance, so there are multiple factors to consider when choosing a Synchronized pulley material.

First, the material of Synchronized pulley should have good strength and stiffness. Synchronized pulleys in drivetrains are subjected to high-intensity and high-torque operating conditions, so the materials must be able to withstand these forces without deforming or cracking. Common Synchronized pulley materials include metals (such as steel, aluminum alloys) and high-strength plastics (such as polyamide, polyurethane, etc.). Metal Synchronized pulleys generally have higher strength and stiffness and are suitable for high-load and high-speed transmission systems, while plastic Synchronized pulleys are relatively lightweight and have lower noise and vibration levels.

Secondly, the material of Synchronized pulley should have good wear resistance and corrosion resistance. During the transmission process, friction will occur between the Synchronized pulley and the synchronous belt, so the material needs to have sufficient wear resistance to reduce wear and extend service life. In addition, some working environments may contain corrosive substances, such as chemicals or humid environments, so the material of Synchronized pulley should be corrosion-resistant. For metal Synchronized pulley, its corrosion resistance can be increased through surface treatment (such as chrome plating, zinc plating, etc.); plastic Synchronized pulley usually has better corrosion resistance.

In addition, the material of Synchronized pulley should also have good temperature stability and high temperature resistance. In some applications, Synchronized pulley may encounter high temperature conditions, so the material needs to be resistant to high temperatures to ensure the normal operation of the drive system. Metal Synchronized pulleys usually have high thermal conductivity and high temperature resistance and are suitable for high temperature environments; while plastic Synchronized pulleys have relatively low temperature resistance and may need to choose high-temperature special plastics or take cooling measures.

Finally, the material selection of Synchronized pulley should also consider cost and manufacturing process. Different materials have different costs and manufacturing processes. Performance requirements and economic realities need to be comprehensively considered to select the most appropriate material.

In short, the material selection of Synchronized pulley has an important impact on transmission performance and durability. Reasonable selection of materials can improve the strength, stiffness, wear resistance, corrosion resistance, high temperature resistance and other characteristics of Synchronized pulley, thereby ensuring the stability, reliability and life of the transmission system. In practical applications, the most suitable Synchronized pulley material should be selected based on specific transmission requirements and working environment.